For a professional CDL truck driver in California, taking your CDL pre-trip inspection checklist California is the most important thing you will do before hitting the road. It’s not just compliance; it’s about being safe, efficient, and avoiding costly breakdowns. Whether you are driving down the Golden State highways or the local streets, a good pre-trip inspection will make sure that your vehicle is ready for whatever lies ahead. Below, you will find a comprehensive CDL pre-trip checklist for California truckers that will go through each key area as one seeks to stay on top of maintenance and avoid any on-road surprises. Get ready to inspect one’s truck like a pro!

Importance of the CDL pre-trip checklist inspection in California

Pre-trip inspection checklists are an integral part of commercial driving in California for reasons of safety and compliance. Here is why this is so important:

- Safety first: A pre-trip inspection assists in finding impending problems that could be unsafe on the road. With a check of all the components, it diminishes the chances of brake failures, tire blowouts, and steering issues that may result in accidents; thus, it secures you and others using the road.

- Compliant with California regulations: California has very stringent specifications regarding commercial vehicles. Failure to comply invites penalties, fines, or being taken out of service. Completion of pre-trip inspection helps in keeping your vehicle within legal operation parameters of the regulation.

- Less downtime and expenses: Early detection of minor problems, such as low levels of fluid or worn tires, reduces the incidence of costly breakdowns and prolonged repairs. Regular pre-trip inspections can save you both time and money by minimizing unexpected maintenance needs.

- Professionalism and accountability: Consistent inspections reflect professionalism, whereby a well-maintained truck serves as a plus for yourself and your employer. This depicts that you are responsible, reliable, and concerned about safe driving.

CDL pre-trip inspection checklist in California

This checklist includes every critical area of your CDL vehicles to help you meet the standards set by the state and avoid any potential fines while keeping your vehicle in top condition. From the engine to the trailer, here’s how you inspect each component in detail for a smooth, compliant journey.

Engine compartment

Make sure that your engine compartment is free of possible hazards, clean, and ready to go. Here’s what to check:

- Engine oil level: Always be sure the oil level is at a safe level using the dipstick.

- Coolant level: Always check the radiator and coolant reservoir to make sure it is filled to an appropriate level.

- Power steering fluid: Make sure the power steering fluid is at a safe level.

- Belts and hoses: Check for cracks, frays, or signs of wear in belts and hoses.

- Battery: Check that the battery terminals are properly tightened and clean of corrosion.

- Leaks: In the ground under the engine, make a check for any signs of leaks, such as oil, coolant, and power steering fluid.

Front of tractor/truck

This section will outline the front of your truck, concerning sight and safety.

- Windshield & wipers: The windshield should be free of debris and not have any cracks in it. Wipers should not show any wear and be working properly.

- Headlights & turn signals: Headlamps (high and low beams), turn signals, and marker lights should be checked for proper operation.

- Mirrors: Clean and correctly adjusted for clear vision.

- Grill & bumper: The grill and the bumper should be looked at for any damage that could obstruct airflow into the engine or the structural integrity of the truck.

Rear of tractor/truck

Carefully check the back of your truck so as not to have any problems driving on the road.

- Light: This is an important feature that needs to be checked to see that the brake lights, tail lights, and reverse lights are all in good working condition.

- Mud flaps: Check they are properly secured and in good condition.

- Reflectors: These are not to be missing or damaged; should be visible and intact.

- Exhaust system: Inspect the exhaust pipe and muffler for damage; ensure there are no leaks where fuel tanks are mounted.

Driver door fuel area

This area ensures both driver safety and fuel containment.

- Fuel tank & cap: Inspect the tank for leaks, and ensure the fuel cap is tightened.

- Door latch & hinges: Confirm the driver’s door goes up and down with no problems and that latch is tight.

- Steps/steps: Ensure steps are clean and free of defects to provide safe access to the cab.

- Mirror mountings: Check the mirror mountings for proper security and adjustments.

Coupling area

Coupling is the most important aspect of safely and stably connecting your trailer.

- Fifth wheel: Be sure it is properly lubricated, securely mounted, and doesn’t show wear.

- Kingpin & locking jaws: The kingpin should be securely attached and locking jaws fully extended.

- Airlines & electrical connections: Check that air hoses and electrical lines are securely connected and will not leak or have exposed wires.

Wheel system (both tractor and trailer)

A good wheel system is essential to hold the handling and the stops of the vehicle.

- Tires: Tread depth should be 1/16″ or more, tire pressures should be at the recommended pressure; and there should not be any visible bulges, cuts, and other damage.

- Rims: Check for any cracks, bends, or rust at lug nuts.

- Lug nuts: All lug nuts shall be tightened, without rust or cracks.

- Hub oil seals: Any indication of leakages of oil in the hub area.

Trailer

Check that the trailer and parts are in good integrity so as not to have your load shifting during your journey.

- Landing gear: Ensure that the landing gear is fully raised upwards and secured.

- Frame & Body: Check for any apparent damage, cracks or rust, especially in the joint and weld areas.

- Doors & latches: The trailer doors and latches are closed, secured, and operational.

- Cargo securement: Check all tiedown equipment is snug and in good condition.

Light check

- Checks on lighting: These are fundamental to view as well as to inform other traffic in the flow.

- Headlights: Make sure that high and low beams are functioning accordingly.

- Turn signals: Check the turn signals, all of them (left and right, front and rear).

- Marker lights: Check all marker lights on the tractor and trailer.

- Brake lights & hazard lights: Check all the brake and hazard lights to see that they work well.

In-cab inspection and brake tests

In the cab, there are several important systems that must be checked before each trip.

- Seat belt: Check the seat belt to ensure it is working and secured properly.

- Horn: Check the city horn and air horn to ensure proper functionality.

- Steering play: Check for excessive steering wheel play, no more than 10 degrees.

- Gauges: Check all gauges, reading oil pressure, coolant, voltmeter proper readings.

- Brakes: Test service brakes, test parking brakes, and perform a tug test.

- Air brakes: Test the air brakes and check the governor cut-out and emergency signals.

Common problems found while doing pre-trip inspection

Certain problems of the CDL pre-trip inspection often have to be faced by truckers and may entail risks on the road or attract fines. Here are some of the common ones:

- Worn or cracked belts and hoses: The belts and hoses wear out with time. A faulty belt or ruptured hose results in overheating of the engine, failure in power steering, and other failures. Check for cracks, frays, and leaks, especially near the clamps and connections.

- Underinflated or damaged tires: The most common problems with tires involve low tire pressure, uneven tread wear, or visible cuts and bulges. Underinflation of tires, along with damage to them, contributes to a reduction in fuel efficiency and may lead to blowouts, which have a great chance of causing serious road hazards.

- Faulty lights: Burnt-out lights usually appear. Faulty lights can decrease visibility and communication with other drivers, increasing the risk of accidents, especially at night or during poor weather.

- Air brake leaks: The air brakes are an integral part that enables huge trucks to stop. Leaks in the air system reduce braking performance significantly. Generally, this condition may be found through air pressure checks and listening for leaks.

- Missing or loose lug nuts: Lug nuts can become loose due to wear and tear. If lug nuts are missing or become loose, the stability of the wheel becomes compromised, and the vehicle should not be driven.

By addressing these common issues, your pre-trip inspection will keep your vehicle safe, reduce unexpected breakdowns, and keep you in compliance with California’s safety standards.

Tips on how to memorize CDL pre-trip inspection Checklist California

The pre-trip CDL inspection checklist can be a long list to commit to memory, but proper strategies will make this second nature. So, how do you make this list easier? Well, here are a few ideas:

- Break it up into sections: A typical pre-trip inspection can generally be divided into categories or groupings: the engine compartment, the wheel system, in-cab inspection, etc. Make it easier to learn by breaking it up into these categories rather than trying to learn it all at once.

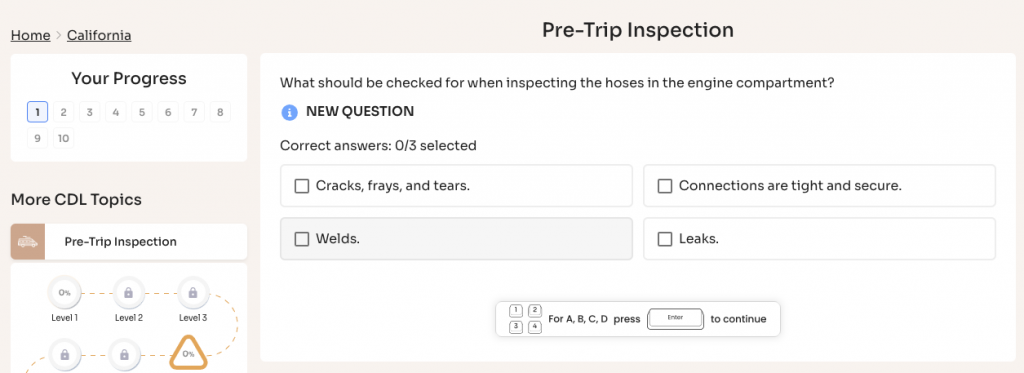

- Take a practice test: While pre-trip inspection is a part of skills tests, the foundation knowledge totally could be learned through multiple questionnaires. Start practice with questions that help you become familiar with vehicle parts and guide you to do a perfect checklist, hence a smoother real test can be completed easier. A sample California CDL pre-trip inspection checklist can be seen below:

Take the California CDL pre-trip inspection practice test now!

- Use mnemonics: Devise mnemonics or acronyms for each area of concentration. For example, to remember the engine compartment, “EBBCL” will remind you to check the Engine oil, Belts, Battery, Coolant, and Leaks. This will help one simplify the information into a more easily remembered pattern.

- Flashcards: You can make flashcards out of each component of the checklist. Going through them every day will help one remember and reinforce them in their brains, and they can also take them anywhere with them just in case.

By incorporating these memorization techniques, you will become comfortable with the checklist, making inspections a quicker, easier, and more reliable part of your routine.

Final thoughts

A CDL pre-trip inspection checklist in California should be done with the greatest caution to ensure everything works in a safe manner, in accordance with the law, and keeps your mind free. Each of the key areas to check has been highlighted to ensure you can perform a thorough check to minimize the risk of accidents on the roads and also put you in compliance with commercial driving requirements in California. Need a reliable guide for your California CDL pre-trip inspection? Follow our checklist to stay in compliance, safe, and ready for any inspection. Start inspecting like a pro today!